|

|

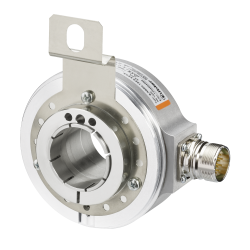

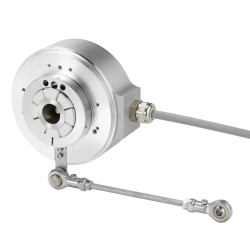

The A02H incremental heavy-duty encoder impresses with its extreme robustness and compact design with a through hollow shaft up to 42 mm. Due to its special design, it is perfect for any application with very harsh environmental conditions.

| Mechanical | |

|---|---|

| Dimension | Ø 100 mm |

| Shaft type | 20 mm hollow shaft, through 25 mm hollow shaft, through 28 mm hollow shaft, through 30 mm hollow shaft, through 38 mm hollow shaft, through 40 mm hollow shaft, through 42 mm hollow shaft, through 5/8 " hollow shaft, through 1 " hollow shaft, through 1 1/4 " hollow shaft, through |

| Flange type | Ø 100.00 mm Ø 115.00 mm |

| Working temperature | -40 °C ... +80 °C |

| Protection level | IP65 |

| Connection types | Radial cable M23 connector radial M12 connector radial |

| Max. rotational speed | 6.000 min-1 |

| Weight | 800 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. | 5.000 ppr incremental |

| Supply voltage | 5 V DC 5...30 V DC 10...30 V DC |

| Interfaces | Push-pull TTL / RS422 SinCos |

| Options | |

|---|---|

| on request |

|

| Innendurchmesser 38mm | 8.0010.4017.0000 |

| Innendurchmesser 12mm | 8.0010.4029.0000 |

| 8.0010.4028.0000 |

| 8.0010.40Y0.0001 |