Description

E+PLC400 is a modular PLC that was specifically developed to comply with strict regulations in heat treatment and other demanding industries. The open platform according to industry standard IEC61131-3 CODESYS® and the unique, integrated programming and visualization environment significantly minimize the configuration effort. Includes extended function block libraries for:

- Applications of heat treatment

- Control and data collection

- “OEM Security” and customization

The devices contain the unique Eurotherm PID control functions for faster commissioning and more precise control of the overall process. The functions also make it easier to comply with legal regulations and end customer requirements. Features include:

- 6 PID sets for control at different setpoints

- Intelligent self-optimization for optimal control and commissioning

- Special cutback functions to avoid overshoots

The data management included in E+PLC400 helps our customers comply with strict data storage regulations:

- Forgery-proof data format .uhh (a better alternative to changeable .csv files in other PLCs)

Ethernet communication offers connection to IIoT (Industrial Internet of Things) and Industry 4.0 technologies.

To support operational efficiency, E+PLC400 features an embedded web server for remote viewing on mobile devices.

Typical fields of application

- Industrial furnaces and blast furnaces

- Climate chambers

- Autoclaves

- Sterilizers

- dryer

- Semiconductor manufacturing

- Special machines and test equipment

Easy to use function block

- library

- Self-optimizing PID control

- Data recording

- Batch data management

- Setpoint programming

- C level control (including 3GASIR and online diffusion)

- Vacuum control (including active measuring device support, auto and leak rate testing)

IEC 61131-3 programming languages

- Ladder Diagram (LD)

- Continuous Function Chart (CFC)

- Function Block Diagram (FBD)

- Instruction List (IL)

- Sequential Function Chart (SFC)

- Structured Text (ST)

specification

Archiving Strategy

Yes

Autotuning PID

Yes

Available I/O Modules

AI8, AO2, D16, DI16, DO16, RLY8, ZI

pa_batch

2173

Communications Protocols

FTP, Modbus Serial RTU (Master/Slave), Modbus, OPC-DA via PC based software (*Contact factory for availability), TCP/IP (Master/Slave)

I/O Expansion Method

Modbus

Mounting

DIN rail

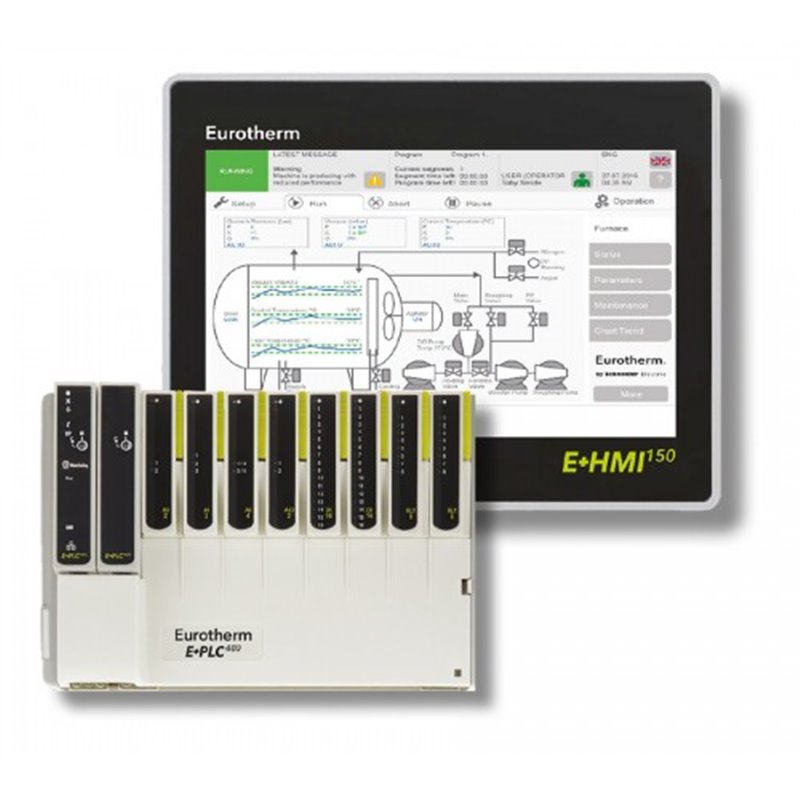

Panel HMI (Protocol)

E+HMI150 (OPC-DA)

Programming Languages

CFC, FBD, IEC61131-3 compliant, IL, LD, SFC, ST

Programming platform

CODESYS (open)

Recording Duration (approx)

Based on 4 chs at intervals of: 1s 50.5 days 10s 1.28 years 20s 2.77 years 60s 8.3 years

Secure recording

Yes

Set point programmer

Yes

AMS2750F

Yes

Web visualization

Yes