COMBIVIS studio 6

Characteristics

Brand:

Item number:

see title

- IEC 61131-3 application development

- Device and library database

- Commissioning and diagnostic assistants

- COMBIVIS studio HMI integration

- Document database

- Large selection of products

- Stockable & individual orders

- Permanently low and transparent prices

COMBIVIS studio 6

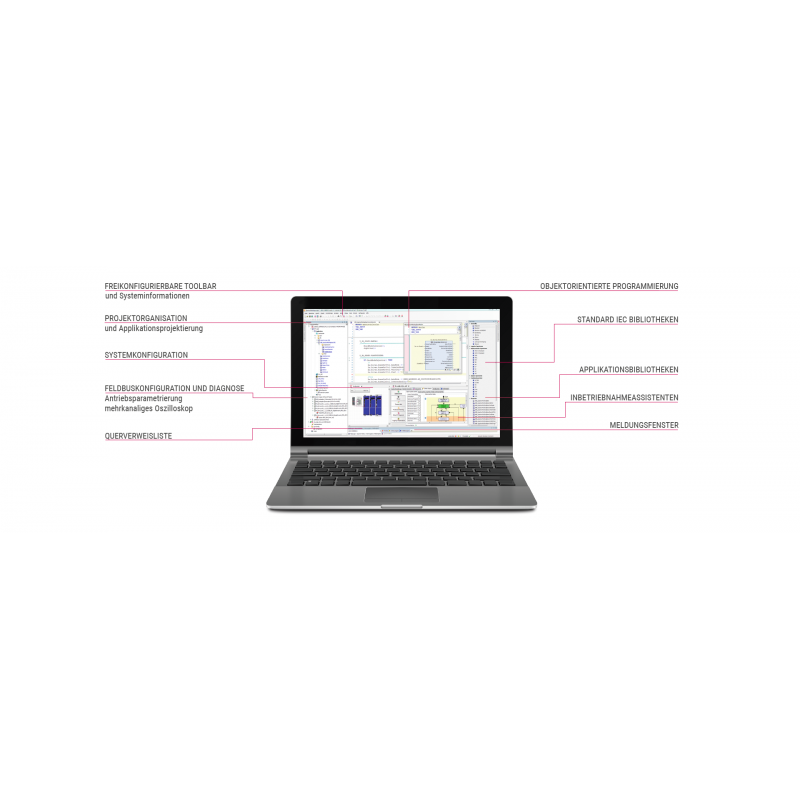

COMBIVIS studio 6 is KEB’s intelligent automation suite. It combines motion control, IEC 61131-3 project generation, wizard-guided component selection, fieldbus configuration and drive parameterization. A software tool is available to the user from the planning and layout phase, through the implementation of control sequences and multi-axis movement profiles, to commissioning and fine-tuning. Based on the extensive library, template and device database, solutions for a wide range of applications can be generated quickly and easily.

COMBIVIS studio 6

In KEB COMBIVIS studio 6, IEC 61131-3 application development and drive parameterization merge to form an efficient engineering tool for individual automation solutions.

The software makes it easy to get started with programming according to IEC 61131-3 and thus creates the basis for independent and future-oriented source codes with a flexible choice of programming languages. Users benefit from convenient “SmartCoding” with tools for declaration, error diagnosis, debugging and online data analysis.

Access to the KEB database also provides time-saving access to operating instructions, technical drawings and data sheets for project creation and documentation.

The KEB libraries provide direct entry into motion programming for real-time capable, synchronously acting drives. Integrated editors support the creation of profiles in the areas of cams, electronic gears, angular synchronous operation and the integration of G codes.

Commissioning assistants, digital oscilloscopes, tools for data backup and recovery as well as extensive expert settings for optimizing fine-tuning of systems complete the COMBIVIS studio 6 engineering software.

To round off the automation concept, KEB offers the fully integrated safety solution based on the CODESYS SAFETY development environment in the COMBIVIS studio 6 automation platform. This complete solution enables freely programmable development for applications with the safety standards IEC 61508 SIL3 and DIN EN ISO 13849-1 PLe.

To enable maximum flexibility, KEB offers the safety protocol Safety over EtherCAT® (FSoE) based on existing EtherCAT® topology, without additional wiring.

CONTROL RUNTIME is the basis for PLC and motion control functionality

- BASIC Basic range of functions for the KEB automation platform (IEC 61131-3 standard and KEB Basic libraries)

- PRO Professional range of functions for the KEB automation platform (cam disks, electronic gear, angular synchronism)

- ADVANCED Advanced range of functions for the KEB automation platform (CNC functionality, G-Code, prepared kinematics)

- CNC HIGH-END solution – for complex requirements, this solution with integrated ISG-CNC kernel offers extensive functions for CNC, robotics and motion control