ER-PL Pilot

Characteristics

Brand:

Item number:

see title

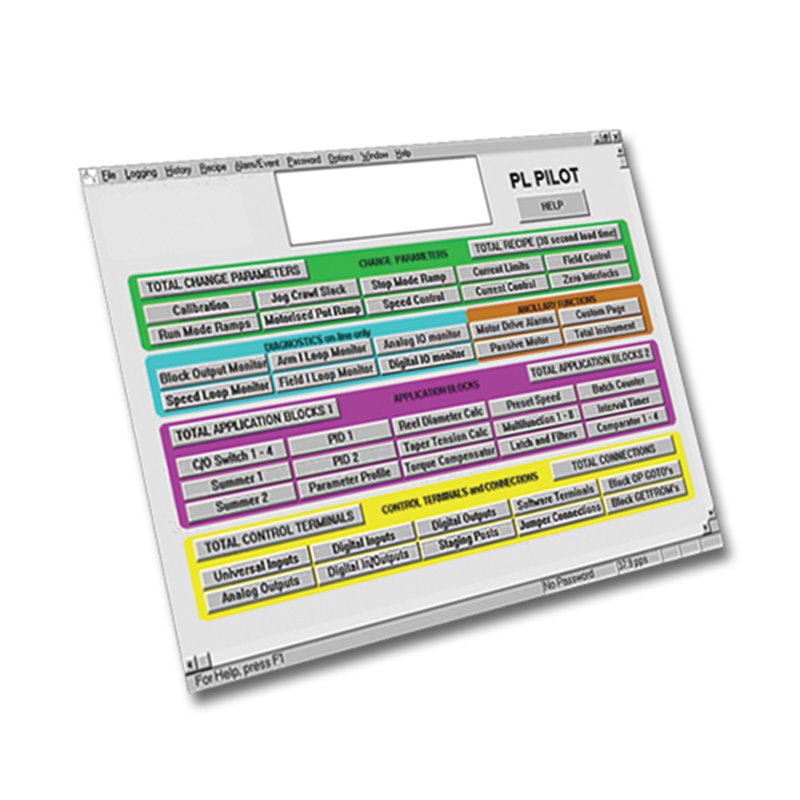

ER-PL Pilot configuration and diagnostic software

A PC based graphical configuration and diagnostic tool for use with the ER-PL and ER-PLX range of digital DC drives. This software is able to greatly simplify the programming, installation and commissioning of the drive.

- Large selection of products

- Stockable & individual orders

- Permanently low and transparent prices

Description

This software makes connecting the drive’s application blocks a breeze and allows the operator to tailor the drive’s control strategy to the needs of the process or application. This capability is further evidence of Eurotherm’s commitment to providing users with cost effective and easy to use DC drive products.

This is a highly intuitive Windows-based software package that does not require knowledge of any programming language. The package can be used in 2 operating modes:

- Offline without a drive connected: The operator can create recipes for drive parameters and block connections.

- Online while a drive is connected: The ER-PL PILOT can also be used to monitor and set the drive parameters.

The PC on which the software runs is connected to the drive via the PC’s standard serial interface. The software package is designed for user-friendly use and provides a clear, defined and understandable method of access at all levels of the comprehensive functionality built into the drive.

This makes system configurations very simple and easy to implement.

Recipe creation and functionality

The ER-PL PILOT has three levels of recipe creation and functionality to meet all requirements:

- Total Recipe (upper level): used to edit the entire range of parameters.

- Bar submenus (2nd level): used to edit the respective main set of parameters.

- Block pages (lowest level): used to edit parameters of the individual blocks in the drive.

Recipes and sections of recipes can be cut and pasted or printed.

The bar submenus (2nd level) represent the 4 main menu bars on the ER-PL PILOT home page:

- Change parameters

- Diagnostic and auxiliary functions

- Application blocks control terminals

Block pages – a paper manual is not required on site

Each bar is equipped with buttons that provide access to a drive block page.

The block pages (bottom level):

Each block has its own page showing the factory default values (shown in blue text) as well as any changed values (shown in black text) with their respective block diagram. In most cases, this eliminates the need for a paper manual – an excellent advantage for on-site commissioning!

Diagnostic monitor

Diagnostics and monitoring in engineering units (volts, amps, kilowatts, rpm, Hz) and percentages for all terminals and block diagram outputs can be displayed in bar graph or panel meter format.